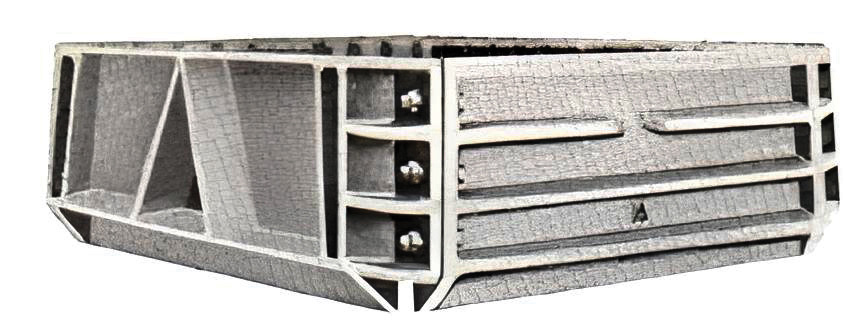

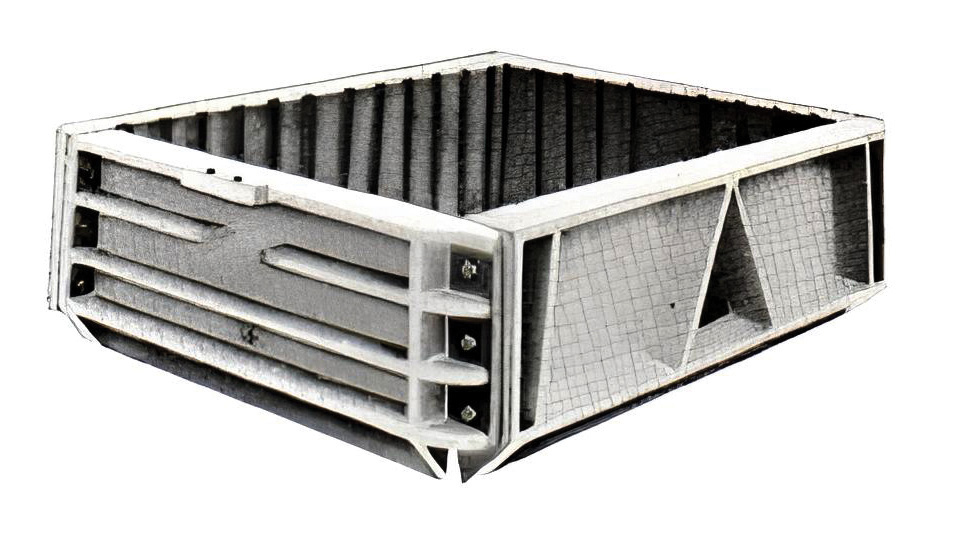

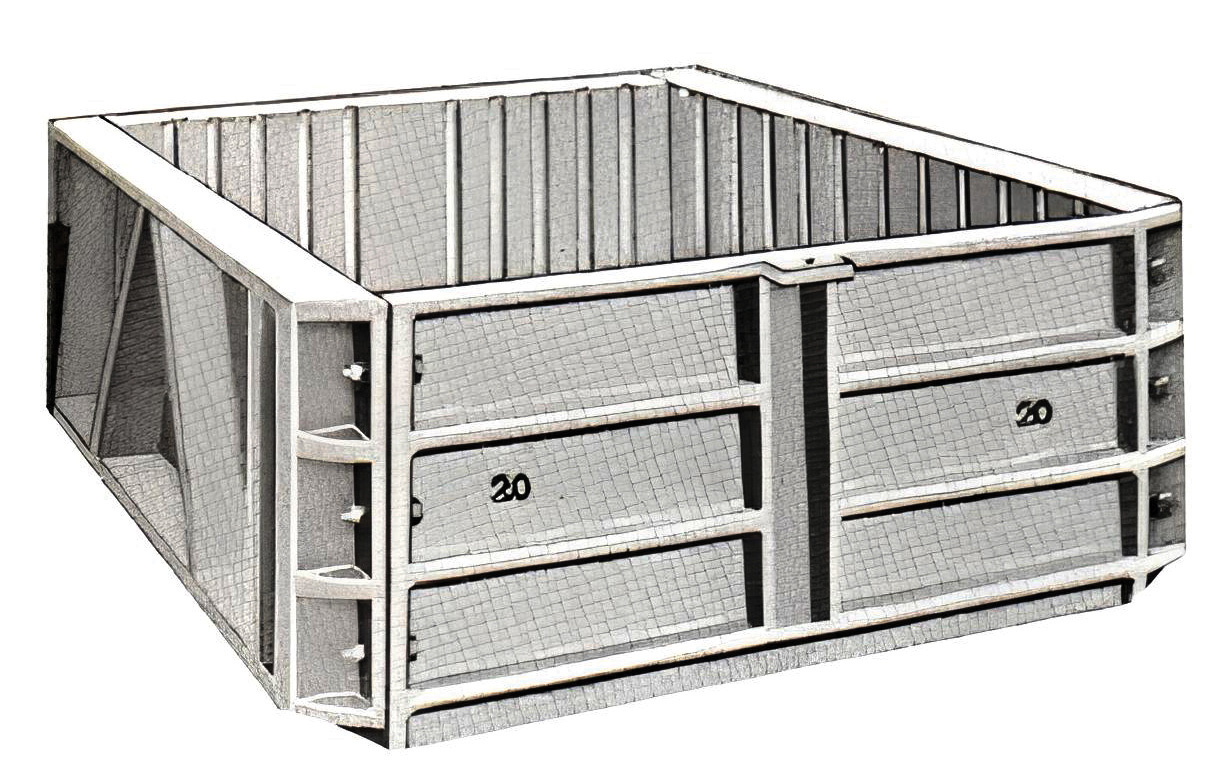

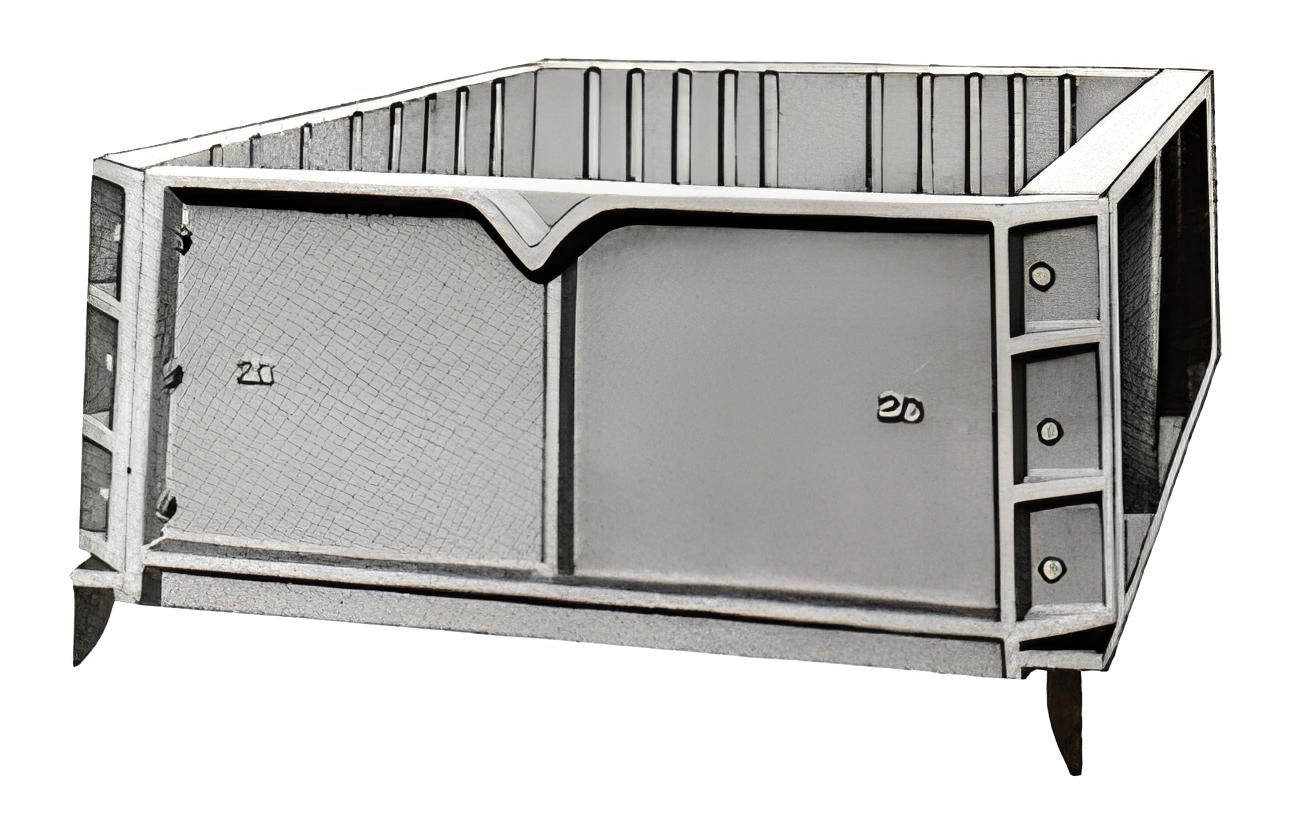

Jackets

Iron & Aluminum Pouring Jackets

DESCRIPTION

Fremont Rigid Jackets are available in either cast iron or cast aluminum, and all Fremont Jackets have a bolted corner construction. These corners are precision machined and drilled on a jig. Inside surfaces are disc ground. With this style of construction, replacement castings can be machined and drilled ready for installation and can be furnished for broken ends or sides. Damaged Jackets that might otherwise be scrapped can be salvaged at a very slight cost, as it is only necessary to remove a few cap screws to install new side or end castings.

Fremont Jackets can be assembled with a 3°, 4°, or 5° taper to match your existing flask.

Jackets are available with inside surfaces that are plain or ribbed. The ribbed construction permits gas to escape more readily and can be helpful for jobs that have gas entrapment problems.

When ordering Jackets be sure to specify the taper and how much of the Jacket is to rest above and below the parting line. This information should be given when ordering replacement castings as well.

Fremont jackets are engineered for most automated systems. The same basic high quality jacket Fremont has been furnishing the foundry industry since 1938 is now specially designed for automated shifting devices.

The Fremont Jackets illustrated are only a few of the special types of jackets that the Fremont Flask Company has furnished to the foundry industry. The Fremont Flask Company would be happy to make jackets for your special applications. Fremont Jackets outperform other jackets and have been proven in the field to reduce scrap. What works so well for other foundrymen will also work well for you.