Flasks

MAGNESIUM Molding Flasks

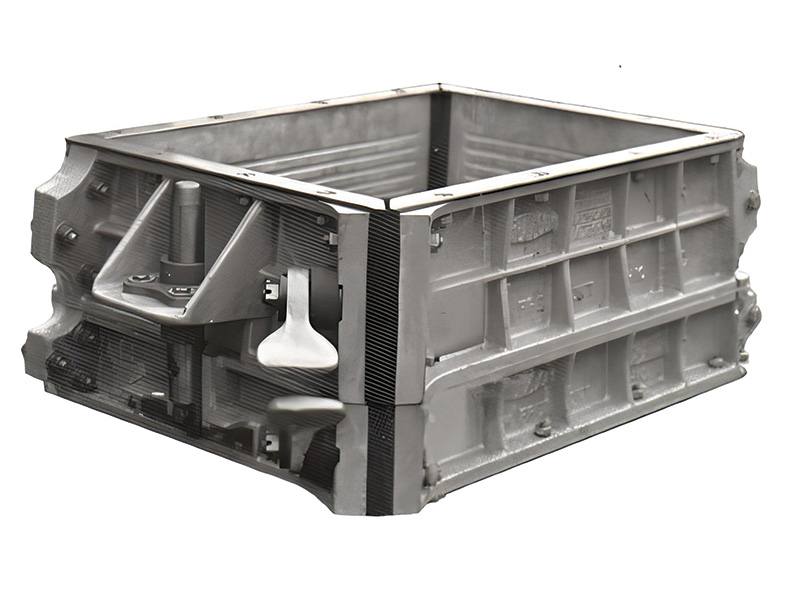

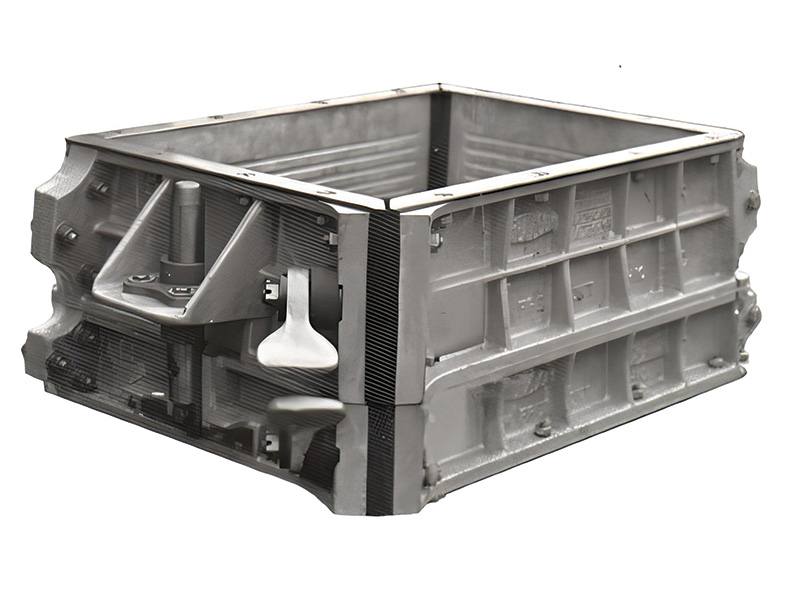

MAGNESIUM SPREADLOCK FLASKS

Spreadlock Flasks are constructed of magnesium. By using this metal, our standard Flask is designed for heavy duty work and is comparable in weight to a medium weight flask constructed from aluminum. Magnesium is well suited for Flask construction as it is one-third lighter in weight, and at the same time, approximately twice the tensile strength of aluminum.

Opening corners are operated with hardened cams with an aluminum lever. Replaceable rubber inserts seal the corner gaps, thus preventing sand from lodging in the corners.

Male and female stops are inserted above and below the cams, giving added strength to open corners and thereby allowing the Flask to maintain perfect alignment indefinitely.

All Fremont Flasks are available in three models

MAGNESIUM “1/2 A” LIGHT-WEIGHT FLASK

DESCRIPTION

The lightest version of the Fremont Flask Company’s iconic Spreadlock flask, the “1/2 A” has solved many problems where weight has become a conscious factor in molding. It features 1″ flanges with overall lighter construction. We have done this without sacrificing the strength of the flask. All custom specifications and options remain the same to ensure continuity.

| Weight | 10" to 24" graduated in even inches. |

| Length | 12" to 24" graduated in even inches. |

| Cope Depths | 4" to 6" graduated in one-half inches. |

| Drag Depths | 3" to 6" graduated in half-inches |

| Pins | 1" Round Groovelock with No. 11 Cope Guides. 11/16" Double Round Pins with No. 8-L Cope Guides. |

| Pin Centers | For 1" Round Groovelock Pins add 3" to length of Flask. 11/16" Double Round Pins can be installed on any practical centers. |

| Flanges | Minimum 3/8" thick x 1" wide in both cope and drag flanges |

| Tapers | 3°, 4°, or 5° are Standard. |

MAGNESIUM “A” Standard-WEIGHT FLASK

DESCRIPTION

The standard Model “A” Fremont Flask is designed for all types of machine production jobs and can also be handled on a bench.

One of the outstanding features of these Flasks is the 1” Round Groovelock Pin and guide which is standard equipment. However, Flasks can be furnished with any other type of pin and guide which a customer may prefer. The method used to attach the Groovelock Pin to the drag, guarantees perfect alignment indefinitely, under normal working conditions. The only maintenance on this type of pin and guide is an occasional adjustment of the guide to take up any slack caused by wear.

All Spreadlock Flasks are jig and fixture drilled and machined. End or side castings are easily replaced. Particular attention is called to the sturdy construction of our tight corners. These corners are assembled by inserting three No. 42 dowel sleeves through which 5/16” cap screws are inserted.

| Weight | 10" to 24" graduated in even inches. |

| Length | 12" to 24" graduated in even inches. |

| Cope Depths | 4" to 6" graduated in one-half inches. |

| Drag Depths | 3" to 6" graduated in half-inches |

| Pins | 1" Round Groovelock with No. 11 Cope Guides. 11/16" Double Round Pins with No. 8-L Cope Guides. |

| Pin Centers | For 1" Round Groovelock Pins add 3" to length of Flask. 11/16" Double Round Pins can be installed on any practical centers. |

| Flanges | Minimum 3/8" thick x 1-3/8" wide in both cope and drag flanges |

| Steel Facing | 1/8" x 1-1/4" Steel facing is attached to top of cope and bottom of drag flanges and parting line upon request. |

| Tapers | 3°, 4°, or 5° are Standard. |

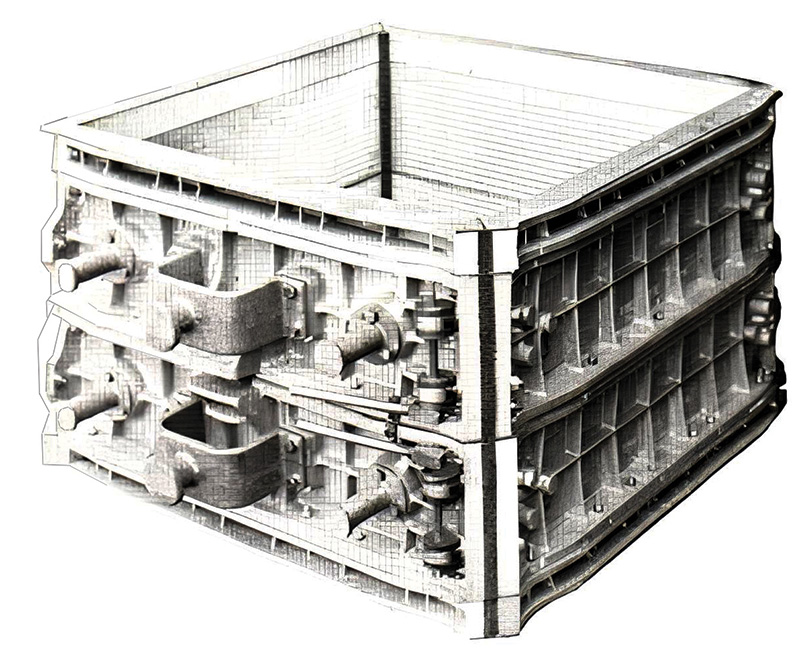

MAGNESIUM “AA” Heavy-WEIGHT FLASK

DESCRIPTION

The Model “AA” Heavy Duty Spreadlock Flasks are designed for all types of heavy production jobs and can be furnished with attachments to fit any type of molding machine. Flanges and ribs are extra heavy to withstand heavy pressures without bowing in the center.

Model “AA” Heavy Duty Flasks are equipped with one set of No. 40 cams in each open corner with No. 41-AMale and Female Stops above and below the cams. On deeper copes and drags, two sets of cams can be installed and if desired these can be connected with a bar and handle for simultaneous operation.

A number of trunnion and handle options are also available to meet the needs of your facility.

| Weight | 20" to 36" graduated in even inches. |

| Length | 20" to 72" graduated in even inches. |

| Cope Depths | 3" to 12" graduated in one-half inches. |

| Drag Depths | 3" to 12" graduated in half-inches. |

| Pins | 1" Round Groovelock with No. 11 Cope Guides. 11/16" Double Round Pins with No. 8-L Cope Guides. |

| Pin Centers | For 1" Round Groovelock Pins add 3" to length of Flask. 11/16" Double Round Pins can be installed on any practical centers. A combination of Round and Hex threaded pins. |

| Flanges | 3/8" to 3/4" thick x 1-3/8" to 2" wide depending on size of flask. |

| Steel Facing | 1/8" x 1-1/4" Steel facing is attached to top of cope and bottom of drag flanges and parting line upon request. |

| Tapers | 3°, 4°, or 5° are Standard. |

| Handles and Trunnions |

No. 85 Chain Trunnions |